Introduction

In the realm of industrial operations, the smooth and efficient functioning of doors is paramount. Whether it's for loading docks, warehouses, or manufacturing facilities, the ability to control door operations seamlessly can significantly impact productivity and safety. Induction loop technology has emerged as a pivotal solution for automating and enhancing the functionality of industrial doors. This article delves into the application of induction loops in industrial door systems, with a focus on the BEA matrix and the unique aspects of China's local induction loop technology.

Understanding Induction Loop Technology

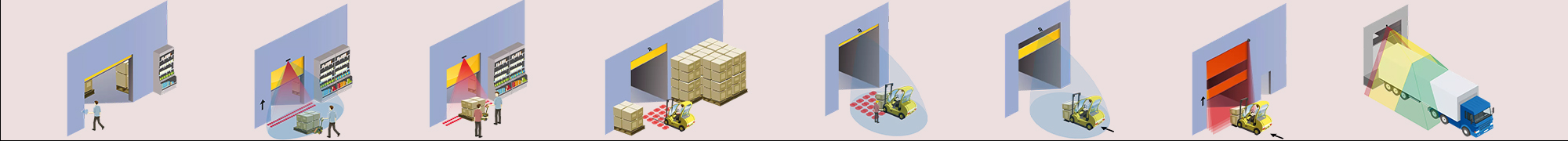

Induction loop systems operate on the principle of electromagnetic induction. A loop of wire is embedded in the floor or the door frame, creating an electromagnetic field. When a vehicle or person equipped with a corresponding detection device passes over or through the loop, it disrupts this field, triggering a response from the door control system. This technology is widely used for automatic door opening and closing, ensuring hands-free operation and enhancing the flow of traffic.

The BEA Matrix: A Cutting-Edge Solution

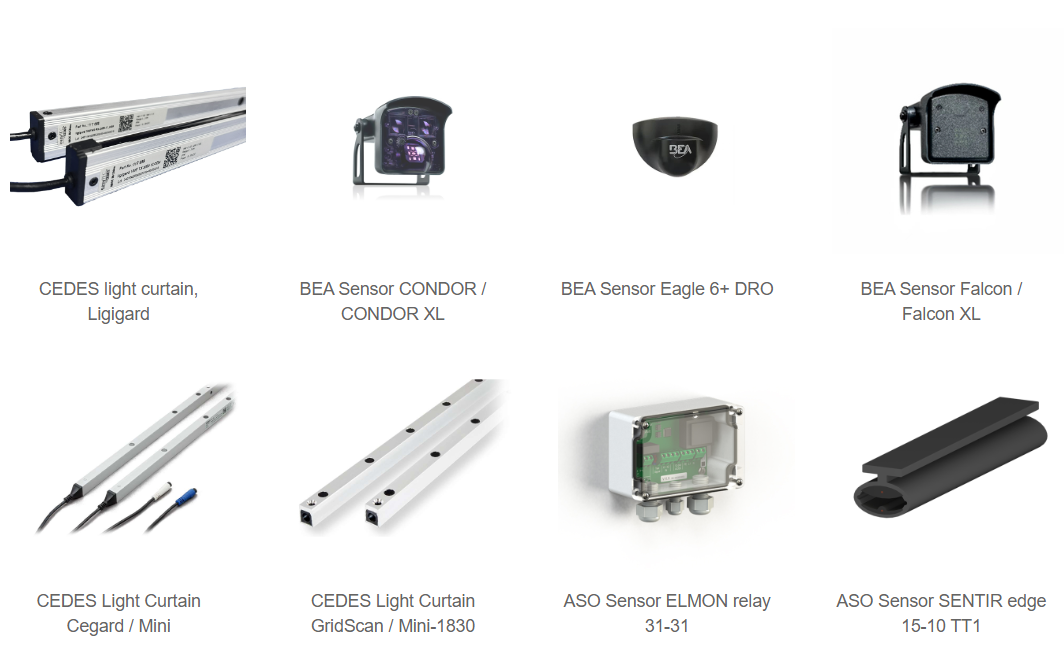

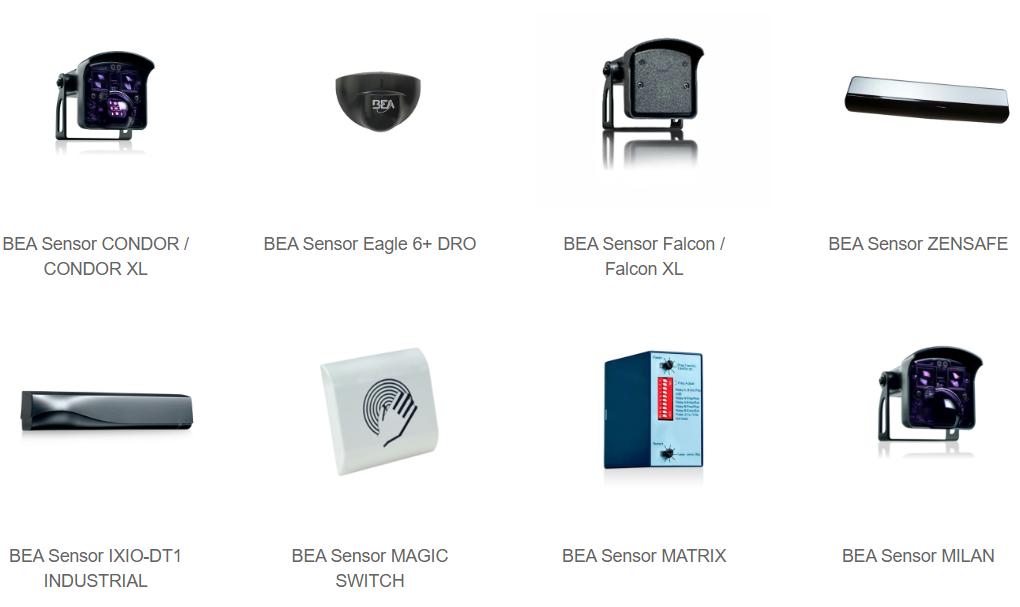

The BEA matrix represents a sophisticated application of induction loop technology. It consists of a grid of induction loops that can be precisely configured to detect specific areas or patterns of movement. This allows for highly customized door operations, such as partial openings for pedestrian traffic or full openings for vehicles, optimizing energy efficiency and safety. The BEA matrix is particularly adept at handling complex traffic scenarios, making it an ideal solution for busy industrial environments.

https://www.highspeeddoor.cn/product/BEA-induction-loop-controller.html

China's Local Induction Loop Innovations

China, with its burgeoning industrial sector, has been at the forefront of developing and implementing advanced induction loop technologies tailored to local needs. Local innovations have focused on enhancing durability, sensitivity, and energy efficiency, making these systems particularly well-suited to the demanding conditions of Chinese industrial facilities. These local induction loops are designed to withstand heavy traffic, extreme weather conditions, and continuous operation, ensuring reliable performance over extended periods.

Benefits of Induction Loops in Industrial Doors

The integration of induction loop technology in industrial door systems offers several key benefits:

Automated Operation: Induction loops automate door opening and closing, reducing the need for manual intervention and enhancing operational efficiency.

Safety: By ensuring doors open and close in response to the presence of vehicles or personnel, induction loops significantly reduce the risk of accidents.

Energy Efficiency: Precise control over door operations minimizes energy loss, contributing to lower operational costs and a reduced environmental footprint.

Customization: Systems like the BEA matrix allow for custom configurations that cater to the specific needs of different industrial settings, optimizing door use for various traffic patterns.

Durability: Especially in the case of China's local induction loop technology, these systems are designed to withstand heavy use and harsh conditions, ensuring long-term reliability.

Challenges and Considerations

While induction loop technology offers significant advantages, there are challenges and considerations to keep in mind. Installation can be complex and costly, particularly in existing structures where retrofitting is required. Additionally, the sensitivity and configuration of induction loops must be carefully calibrated to avoid false triggers or missed detections. Ongoing maintenance is also crucial to ensure the system operates effectively over time.

https://www.highspeeddoor.cn/Sensors.html

Conclusion

Induction loop technology represents a significant advancement in the automation and efficiency of industrial door operations. With solutions like the BEA matrix and the innovative approaches developed in China, these systems are becoming increasingly sophisticated and reliable. By enhancing safety, energy efficiency, and operational flexibility, induction loops are poised to play a critical role in the future of industrial door technology. As the industrial sector continues to evolve, the integration of smart, responsive door systems will be key to maintaining competitive edge and ensuring the safety and productivity of operations.

How does the BEA matrix enhance the functionality of industrial doors?

The BEA matrix enhances the functionality of industrial doors by offering a sophisticated and customizable solution for automating door operations.

Here's how it achieves this:

Precise Detection and Response: The BEA matrix consists of a grid of induction loops that can be finely tuned to detect specific areas or patterns of movement. This precision allows the system to respond only to relevant triggers, such as the approach of a vehicle or pedestrian, minimizing unnecessary door movements and optimizing energy efficiency.

Customizable Operation: One of the key strengths of the BEA matrix is its flexibility. It can be configured to suit the unique needs of different industrial settings. For example, it can be set to open doors partially for pedestrian traffic or fully for vehicles, ensuring that door operations are always appropriate for the context.

Enhanced Safety: By providing precise control over door movements, the BEA matrix significantly enhances safety. It reduces the risk of accidents by ensuring that doors open and close in a predictable and safe manner, accommodating the flow of traffic without posing a hazard to vehicles or personnel.

Improved Traffic Management: In busy industrial environments, managing the flow of traffic through doors is crucial. The BEA matrix can be programmed to handle complex traffic scenarios efficiently, ensuring smooth operations and minimizing congestion. This is particularly beneficial in settings with high volumes of both vehicle and pedestrian traffic.

Energy Efficiency: The ability to customize door operations according to specific triggers and patterns helps in reducing energy consumption. By ensuring that doors open only when necessary and to the extent required, the BEA matrix contributes to lowering operational costs and reducing the environmental impact of industrial facilities.

https://www.highspeeddoor.cn/BEA-Sensor.html

In summary, the BEA matrix enhances the functionality of industrial doors by offering a highly customizable and responsive automation solution that improves efficiency, safety, and energy management. Its advanced features make it particularly well-suited for modern industrial settings with complex traffic and operational requirements.

Company Name:Shanghai Honwei Automation Co., Ltd. HITCH (SHANGHAI) IMPORT& EXPORT CO., LTD.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:sales.sh@powever.com.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800