Clean rooms are specialized environments designed to maintain a high level of cleanliness and control over factors such as temperature, humidity, and particulate matter. These environments are crucial in industries such as pharmaceuticals, electronics, and biotechnology, where even the smallest contaminants can compromise product quality and safety. High-speed zipper doors have emerged as a critical component in maintaining the integrity of these controlled environments. This article explores the application of high-speed zipper doors in clean rooms, highlighting their benefits, design features, and specific use cases.

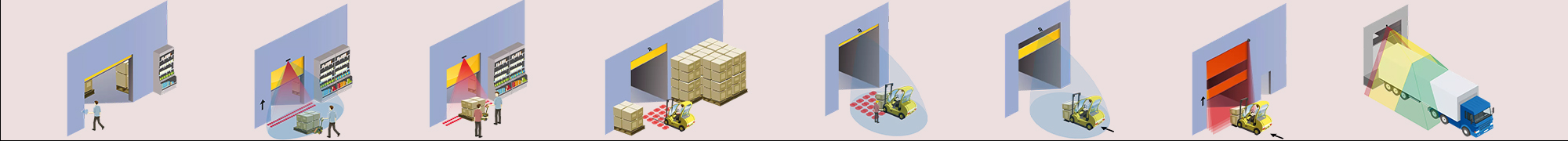

High-speed zipper doors are designed to minimize air exchange and reduce contamination risks, making them indispensable in clean room applications. These doors quickly open and close, ensuring that the environment remains sealed and controlled. The rapid movement of the door helps to prevent the ingress of contaminants, which is essential for maintaining the cleanliness and sterility of the clean room.

High-Speed Operation: High-speed zipper doors can open and close at speeds of up to 2.0 m/s, significantly reducing the time that the door is open and thus minimizing the risk of contamination.

Sealing Performance: These doors are equipped with tight seals that prevent air leakage and maintain the pressure differential within the clean room. This is crucial for maintaining the desired environmental conditions and preventing the entry of contaminants.

Soft Curtain Design: The use of soft curtains made from high-quality materials ensures that the door can withstand frequent use without wear and tear. The curtains are designed to be free of metal parts, reducing the risk of particle generation and ensuring a clean environment.

Safety Features: High-speed zipper doors often include safety features such as safety photoelectric sensors and bottom safety airbags to prevent accidents and ensure the safety of personnel.

In the pharmaceutical industry, high-speed zipper doors are widely used in clean rooms, laboratories, and production areas. These doors help maintain the sterility and cleanliness required for the production of pharmaceutical products. For instance, a leading pharmaceutical company has successfully implemented high-speed zipper doors to control environmental fluctuations and ensure product quality.

The electronics industry also heavily relies on high-speed zipper doors to protect sensitive electronic components from contamination. These doors are used in clean rooms where the production of semiconductors and other electronic devices takes place. The rapid opening and closing of the doors minimize the risk of particle contamination, which can affect the performance and reliability of electronic products.

In the food industry, high-speed zipper doors are used to maintain hygiene and prevent cross-contamination in food processing areas. These doors are particularly useful in high-humidity environments, where maintaining a clean and controlled atmosphere is essential for food safety and quality.

When designing and installing high-speed zipper doors in clean rooms, several factors need to be considered to ensure optimal performance and efficiency:

Clean Room Standards: The doors must comply with international clean room standards, such as ISO 14644, to ensure they meet the required cleanliness levels.

Sealing and Insulation: The doors should have excellent sealing and insulation properties to maintain the desired environmental conditions within the clean room.

Durability and Maintenance: The materials used in the construction of the doors should be durable and easy to maintain, ensuring long-term performance and reliability.

Integration with Existing Systems: The doors should be seamlessly integrated with existing HVAC and air filtration systems to maintain a consistent and controlled environment.

High-speed zipper doors play a vital role in maintaining the integrity of clean rooms across various industries. Their high-speed operation, sealing performance, and safety features make them an essential component in ensuring the cleanliness and sterility of controlled environments. By minimizing air exchange and reducing contamination risks, these doors contribute significantly to the efficiency and quality of production processes in pharmaceuticals, electronics, and food industries. As technology continues to advance, high-speed zipper doors will likely become even more sophisticated, further enhancing their effectiveness in clean room applications.

Company Name:Hitch (Shanghai) Automation Co.,Ltd.

Name: Lucky Gao

Mobile:15901664615

Tel:+86 21 61767181

Whatsapp:+8615901664615

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800