Under the fast-developing of Industry 4.0 and smart manufacturing, the deep integration of servo motors and control systems has emerged as a core driver for enhancing production efficiency and precision. The deep integration of servo motors and control systems has emerged as a pivotal catalyst in manufacturing innovation.This technological synergy significantly boosts production efficiency by optimizing motion control and reducing operational latency.In addition, it elevates industrial precision through real-time data feedback mechanisms and adaptive algorithm-driven adjustments.

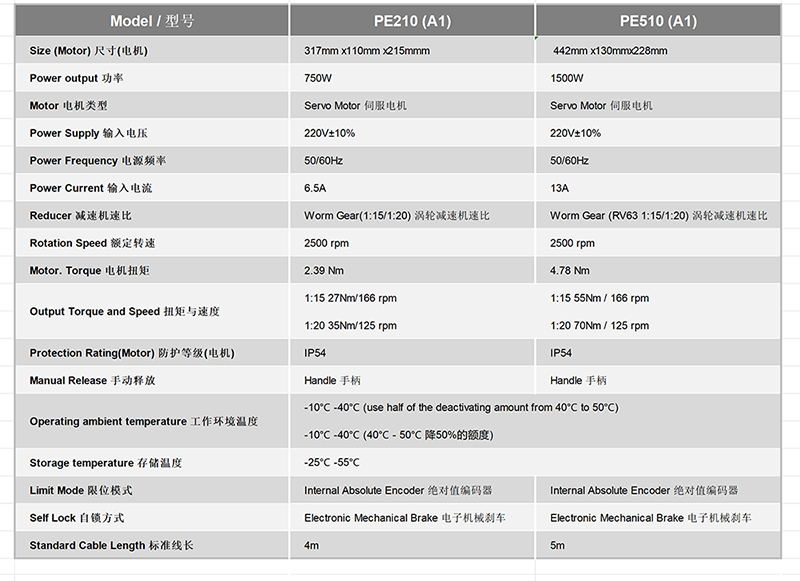

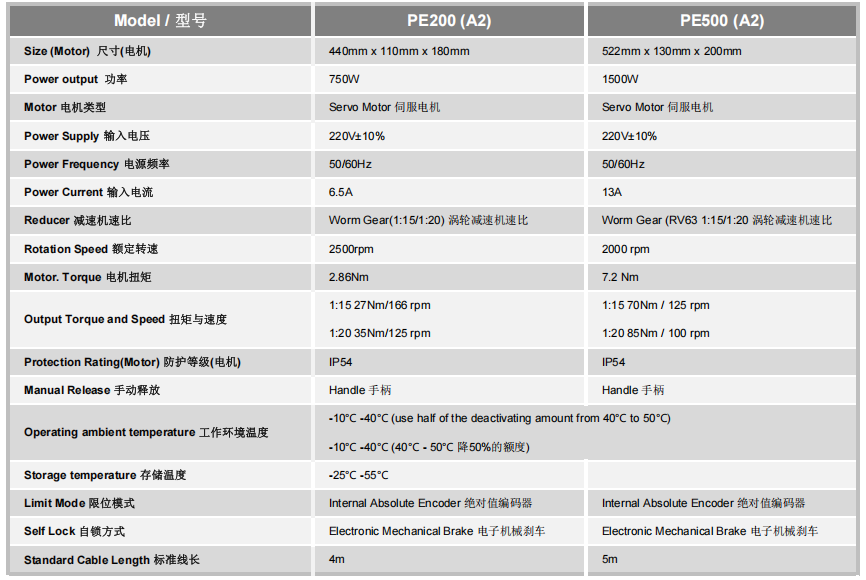

1. Precision Synchronization of Servo Motors and Controllers

In today's factories, motion control isn't just about starting and stopping machines anymore. It's about hitting targets thinner than a hair and reacting faster than a blink. We can imagine it as a robotic arm for placing microchips. If it's off by a speck of dust, the whole product's ruined.

2. System Adaptability and Energy Efficiency of 220V AC Servo Motors

Internet connectivity also allows machines to react instantly to changes. Imagine a packaging line where boxes of different sizes arrive randomly. Guided by real-time sensor data, servo motors can adjust speed or force at any time without waiting for instructions from remote computers. The edge computing reduces latency and makes the whole process smoother. The 220V AC servo motor shines here. Even if the task keeps changing, it can provide strength and efficiency.

In short, combine central control with Internet intelligence to turn a rigid factory into a flexible and self improving system. Machines can not only obey, but also collaborate and optimize themselves over time.

3. Saving Energy Without Sacrificing Power

In industries, keeping machines running efficiently is as important as keeping them powerful. Smart control systems now help servo motors do both. Think of it like a car that automatically adjusts its speed to save fuel while still having enough power to climb hills.

Modern controllers analyze how much energy a servo motor actually needs for a task. For example, if a conveyor belt is only half full, the system can reduce the motor’s speed gently, cutting energy use without slowing production. The 220V AC servo motors are designed to handle these adjustments smoothly, delivering strength when needed but sipping power during lighter loads.

The fusion of smart control systems with servo motors represents a paradigm shift in industrial automation. By harmonizing 220V AC servo motors with multi-protocol controllers and IoT-enabled PLCs, industries achieve unprecedented precision, adaptability, and connectivity. As factories transition toward Industry 4.0, this integration will remain pivotal in driving sustainable, data-driven manufacturing—where every motor rotation is optimized for peak performance.

In essence, the future of automation lies not just in powerful hardware, but in the intelligence that binds it all together.

Company Name:Shanghai Honwei Automation Co., Ltd. HITCH (SHANGHAI) IMPORT& EXPORT CO., LTD.

Name: Phyllis Liang

Mobile:+86 15316076035

Tel:+86 21 61767181

Whatsapp:+86 15316076035

Email:info@highspeeddoor.cn

Email:kevin.jiang@powever.com.cn

Add:Room 301-302, Building 1, No. 1355, Chengbei Road, Jiading District, Shanghai

Post code:201800